Diamond Core Drilling

Diamond core drilling is a common technique in the mining industry for extracting core samples. It is ideal for geotechnical work in semi-consolidated/cemented rock to hard rock environments. Downward pressure and high rotation rates advance drill bits that are faced with diamond impregnated steel. Down pressure and fluid circulation are carefully monitored during drilling. Rock core samples are typically returned using an efficient wireline system. There is a wide selection of drill bits to choose from based on rock types and core sizes. Cascade typically uses a wireline coring system for hard rock applications to obtain core samples and Rock Quality Designation (RQD).

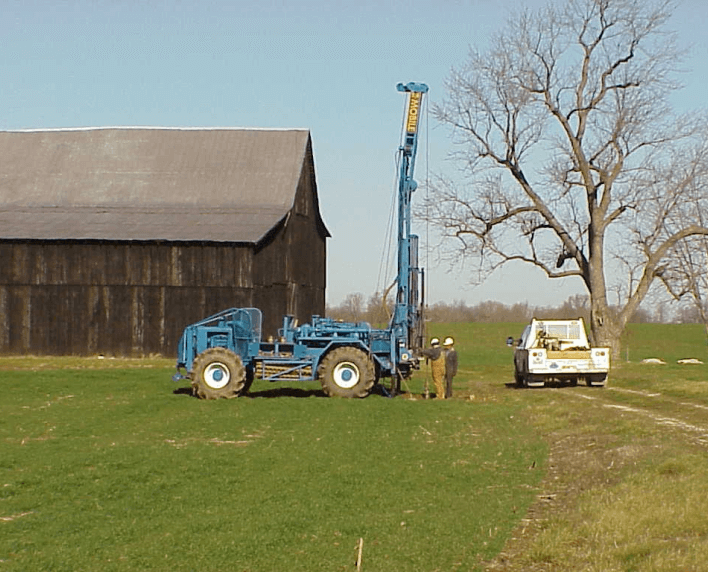

Auger Drilling

Hollow stem auger drilling is a proven and relatively inexpensive technique for a wide range of environmental and geotechnical applications including sampling, installation of monitoring wells and data collection instruments, and subsurface improvements. Different cutter head designs can be utilized based on geology. Soil samples are easily obtained by lowering and advancing a variety of different sized split spoon samplers through the hollow stem augers and out in front of the bit face. This technology is ideal for drilling through unconsolidated alluvial deposits such as sands, silts and clays. The augers maintain bore hole integrity and facilitate soil sampling and well installation. It is the perfect application for environmental sampling because there are no additives, such as mud, used during the drilling process. Depth limitations will vary based on lithology.

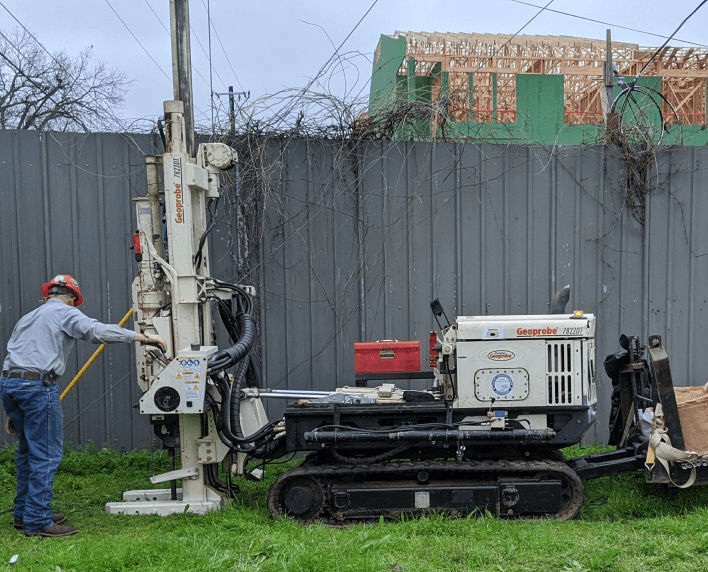

Direct Push

Direct push technology, often referred to as DPT, uses the static weight of the rig combined with a hydraulic hammer to advance tooling or instrumentation through the subsurface. Direct push is ideal for smaller sites because it requires less space for operation and drills smaller holes. Unlike rotary, the drill cuttings are not removed from the hole. The speed and depth of penetration is largely dependent on the soil type, the size of the sampler, and the weight and power of the rig. These systems can be used to perform subsurface soil, water or vapor surveys. They are capable of obtaining soil and groundwater samples, installing standard and pre-packed monitoring wells, and have geotechnical capabilities when equipped with 140 lb. hammer. They can drill and set piezometers, inclinometers, and vapor points; and support injection of a variety of remediation compounds.